BLOG 277 – Why risk the future of your business by not managing its waste?

Eliminating waste from your business with lean thinking can seem like an overwhelming task, but this does not have to be the case.

Lean thinking and managing waste are ultimately focused on value.

Every process in your business either delivers value for your customers or it doesn’t.

Reduce the waste in a process and you either reduce costs or impress customers, or both.

With the right approach, you’ll quickly prove to yourself that managing waste pays off.

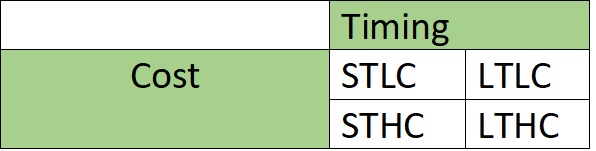

Waste reduction strategies come in 4 categories:

- Short-term low-cost (STLC)

- Long-term low-cost (LTLC)

- Short-term high-cost (STHC)

- Long-term high-cost (LTHC)

This forms part of the Time-Cost Grid:

To start with, you are looking for STLC (short-term low-cost) ways in which to reduce waste in your business. STLC waste reduction means it will pay off for you and your team quickly.

There might only be a few small changes, but these could have a big impact on you, your team and your business. Just like the headteacher getting a set of keys cut for every teacher at a local school, a simple action allowed the school to regain 1,300 lost hours of teaching over a 13-week term.

Toyota is famous for involving its team in improving processes and reducing waste. Your team is at the heart of your business, so don’t you think this is something you should do too?

If you don’t, you will be ‘wasting’ the valuable insight of the people closest to the work and ideally placed to identify the waste within your business.

Click here to learn how to apply the STLC reduction to your waste with the help of your team, a flip chart and some post-it notes.